PLUG WELDS for ELECTRON BEAM WELDING

"PLUG WELD" FOR ELECTRON BEAM WELDING

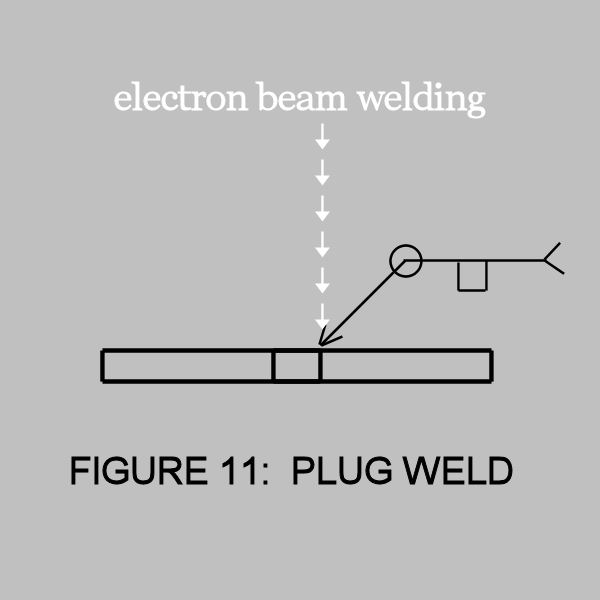

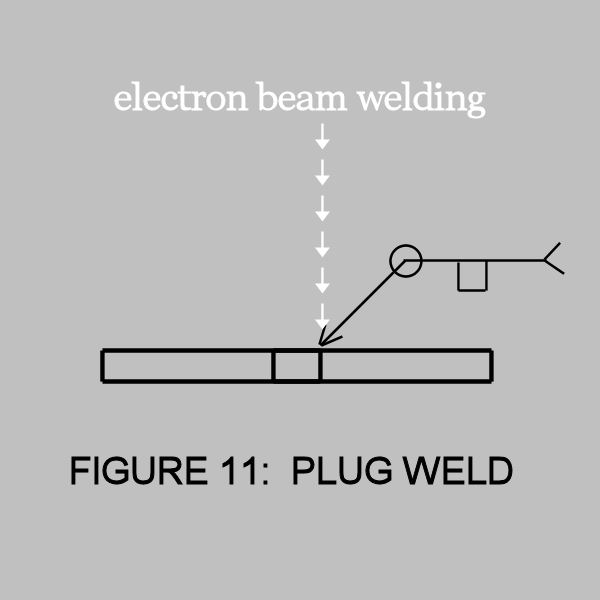

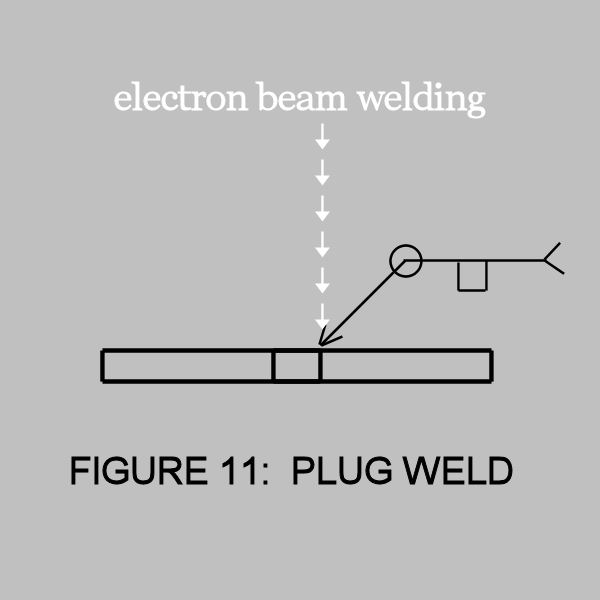

FIGURE 11

The simple plug weld illustrated in Figure 11 works well with most materials provided the

fit-up is tight, with an interference fit being preferred.

With materials such as titanium and magnesium, undercutting can become a problem. In these cases, a plug with a "top scab", as depicted in Figure 12 is recommended.

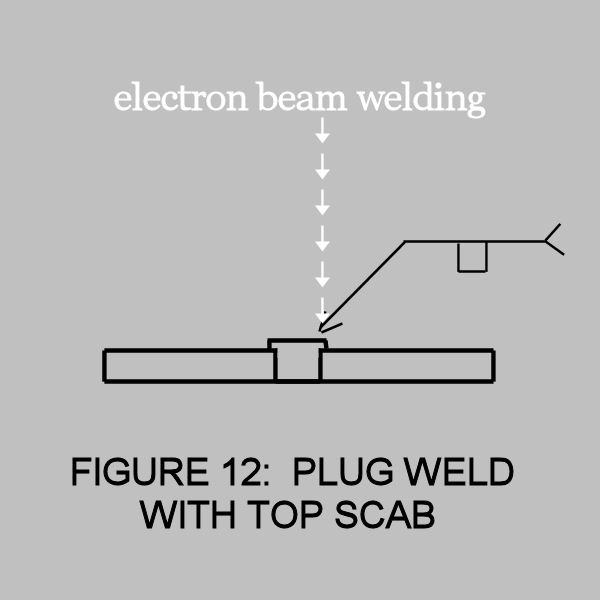

"PLUG WELD with TOP SCAB" FOR ELECTRON BEAM WELDING

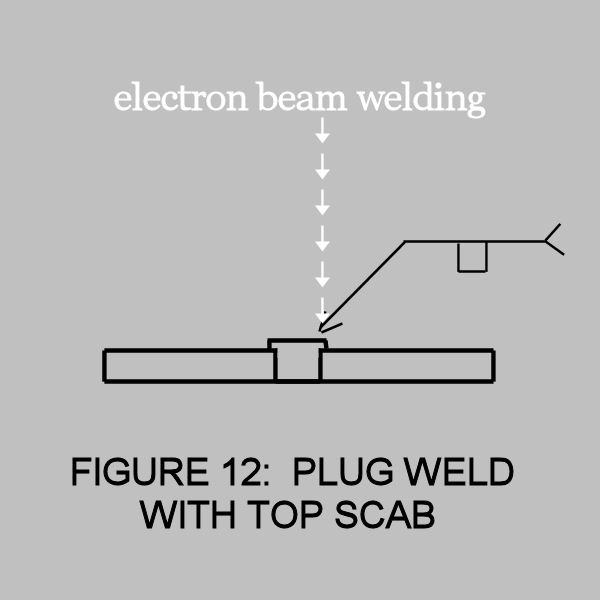

FIGURE 12

With materials such as titanium and magnesium, undercutting can become a problem. In these cases, a plug with a "top scab", as depicted in Figure 12 is recommended.

When welding this type of "scab" joint, as in any blind weld, the use of scribe lines is recommended to aid in the optical tracking of the joint.