"T" JOINT WELDS for ELECTRON BEAM WELDING

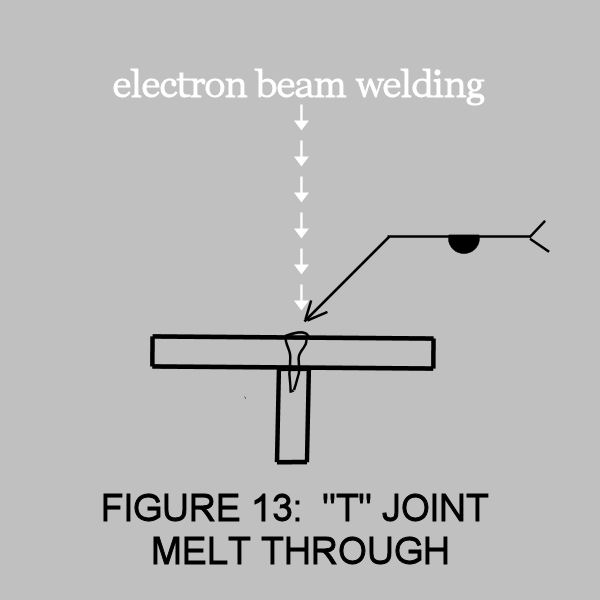

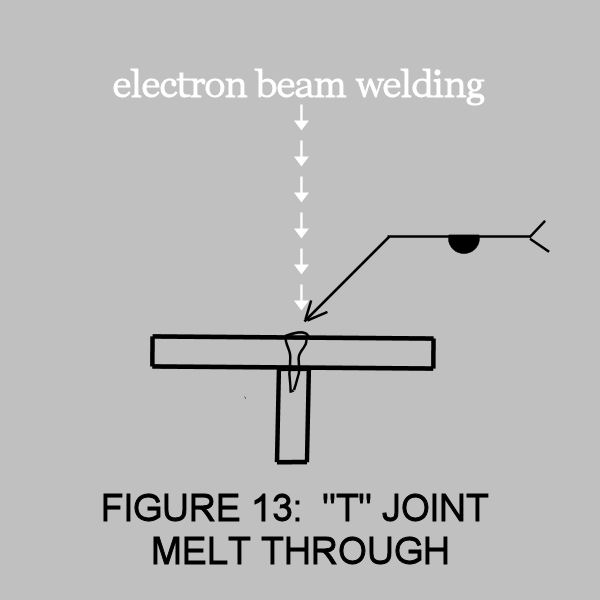

" 'T' JOINT MELT THROUGH" FOR ELECTRON BEAM WELDING

FIGURE 13

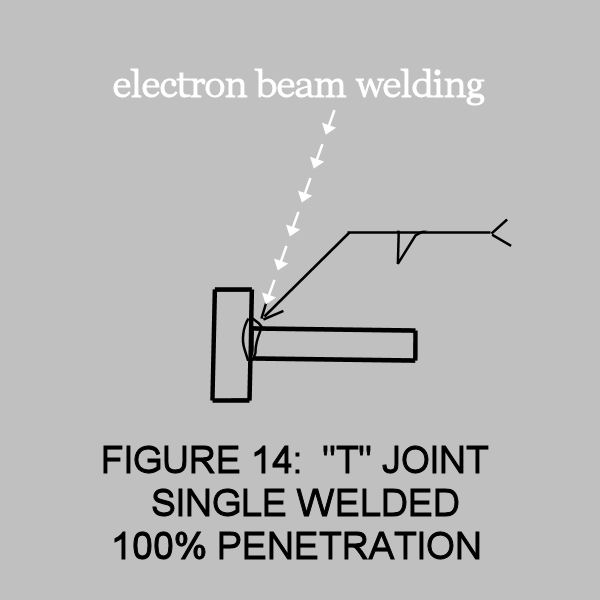

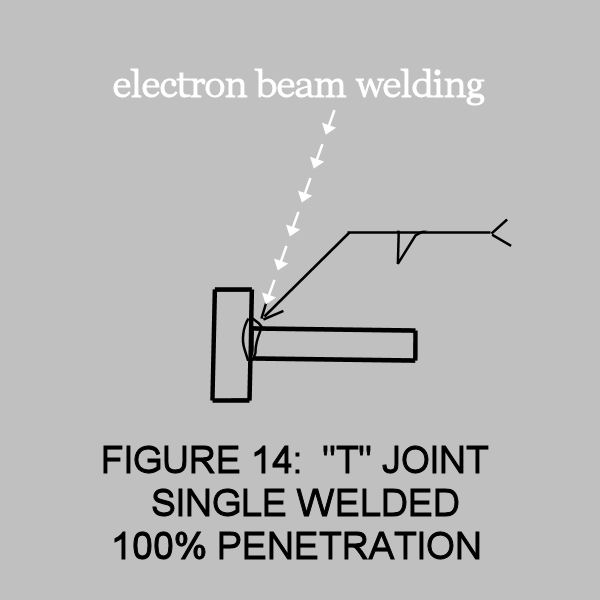

"SINGLE WELD "T" JOINT" FOR ELECTRON BEAM WELDING

FIGURE 14

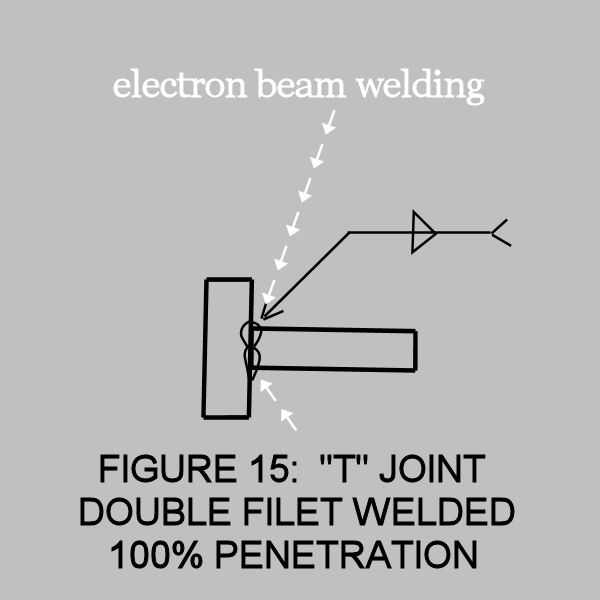

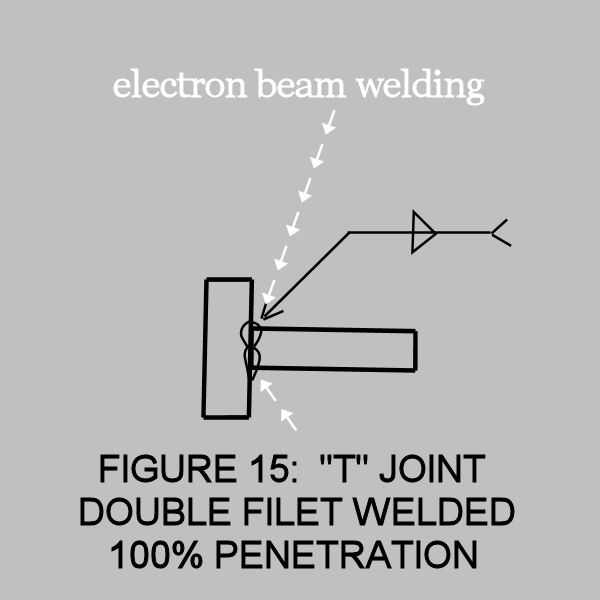

"DOUBLE FILLET WELD "T" JOINT" FOR ELECTRON BEAM WELDING

FIGURE 15

Quality system surveys welcome!

Six EBW systems available!

Visit our facility!

"T" JOINT WELDS for ELECTRON BEAM WELDING

" 'T' JOINT MELT THROUGH" FOR ELECTRON BEAM WELDING

FIGURE 13

"SINGLE WELD "T" JOINT" FOR ELECTRON BEAM WELDING

FIGURE 14

"DOUBLE FILLET WELD "T" JOINT" FOR ELECTRON BEAM WELDING

FIGURE 15